A new material for the next-gen of BBs

First introduced in our OSPW+ series, thermo-formed carbon is lighter, stronger and more stable than alloys and plastics used commonly on BBs. These properties make it the best material not only for threaded BBs but specially for Press-Fit systems. A more stable material against weather conditions makes the BB less prone to produce the infamous creaking noises of Press-Fit systems.

Carbon is not the only exclusive material on Ridea 6CBB. Nylon bearing spindle sleeves increase performance and ease installation. Nylon is flexible for better adaptability to the spindle and it is not affected under extreme weather conditions.

Easy installation

Press-Fit BBs require expensive tools, skills, and more often than not, time. The whole range of 6CBB can be easily installed in few minutes with simple tools in a similar way as with threaded BBs.

Besides, the frame BB shell suffers less mechanical stress while installing and uninstalling the 6CBB, increasing the lifetime of the frame.

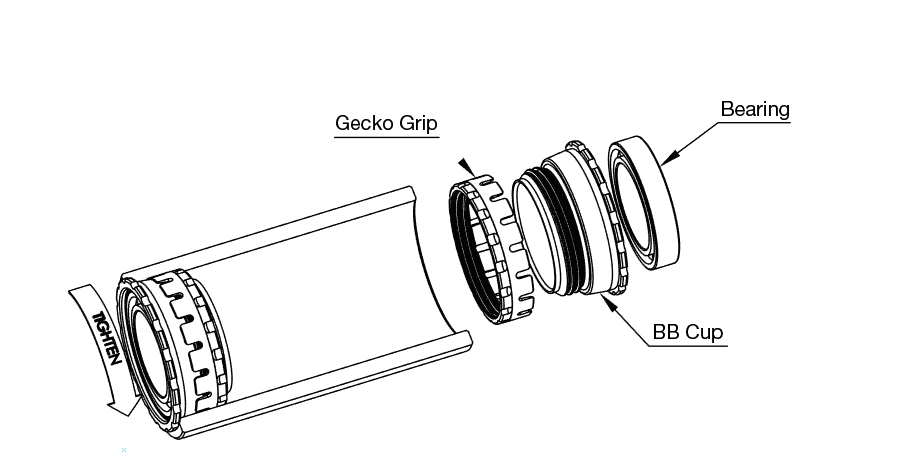

Gecko Grip technology

Press-Fit systems are known for generating creaking noises if conditions are not perfect. The Gecko Grip technology consists of a threaded BB cup with a sloping attack angle and the Gecko Grip ring. While you thread the BB cup inside the frame, the ring increases its diameter due to the sloping attack angle. This creates a tight connection between the frame and the bottom bracket even in frames with wide tolerances, which eliminates any creaking noise.